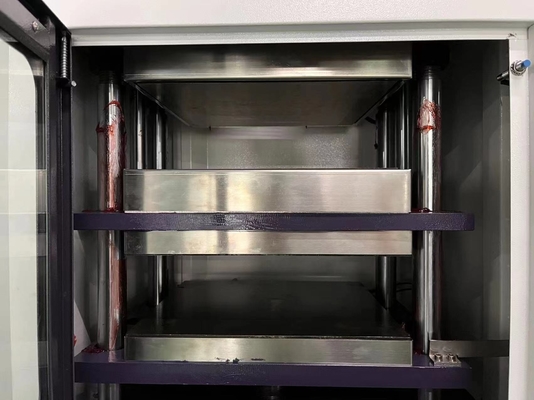

Double-layer small flat vulcanizer

(Electric heating and water cooling)

►Application:

This series of flat vulcanizers are the main equipment for pressing and molding various rubber model products and non-model products, and can also be used for pressing various thermosetting plastics and foaming rubber and plastic products. It has independent power mechanism and electrical system, and adopts button centralized control. The working pressure and heating temperature can be adjusted within a certain range. This model is divided into manual and semi-automatic.

►Features:

01. The main body of the equipment adopts seamless welding technology.

02. The exterior is treated with high temperature baking paint to prevent rust.

03. The upper and lower heating platens are quenched by tool steel, which is rust-proof, wear-resistant and high-hardness.

04. The parallelism of the upper and lower heating plates:0.1mm;Flatness of platen: 0.03MM.

05. Temperature uniformity within 1 degree.

Adjustable pressure.

07. Independent research and development of program controllers.

08. Taiwan Delta PLC touch screen operation, more convenient, faster and more beautiful.

09. Programmable control experiments to obtain more specific and real experimental data.

►Characteristics

1. Independent control system, which can shield the operation interference information source.

2. Separately control the electric box: The shield cannot work normally in a high temperature environment due to the influence of the high temperature in the experiment.

3. The equipment is equipped with multiple protection devices: leakage protection, over-temperature protection alarm, low-voltage protection, operation protection, and emergency shutdown.

4. The equipment has its own exhaust gas discharge system. During the test process, the exhaust gas is discharged from the laboratory to the designated space to ensure the hygiene of the laboratory.

5. The device comes with three-color light alarm.

|

Project 型号

Model

|

LY-6014C-10 |

LY-6014C-30 |

LY-6014C-50 |

| Pressure Capacity |

10T |

30T |

50T |

| Pressure Gauge |

The double node pressure is adjustable, and the pressure adjustment accuracy is 10% |

| Platen Size (mm metric) |

250*250/300*300/350*350/400*400/450*450/500*500/600*600【mm】 |

|

Hot Plate Material

|

High temperature resistant imported steel plate, surface carbonization and quenching, special treatment for fast heat conduction, parallel pressure and no deformation, wear-resistant. |

| Platen Hardness |

50~60HRC |

| Platen Flatness |

≤0.03mm |

| Platen Parallelism |

≤0.16mm |

| Temperature Range |

Normal temperature -250°C [customizable maximum temperature of 500 degrees] [choose one based on the quotation] |

| Temperature Uniformity |

1.5℃【The bigger the platen, the higher the temperature, the worse the temperature uniformity】 |

| Temperature Controller |

Precision module, with PLC touch screen control, touch screen display, numerical display. |

| Temperature Control Method |

The temperature control motherboard is precisely controlled, and the self-tuning is matched with high-precision sensors. The temperature control accuracy is ±1.0 °C. |

| Timer |

The setting display in the touch screen, the time range is 0.1S~99min~9.9hr |

| Heater |

Heating mold built-in cylindrical type [Configure different power according to the platen area, package platen temperature uniformity, not the same power] |

| Heating Time |

Room temperature~160℃ takes about 15min |

| Two Hot Plates |

The hot plate can be set separately to control the temperature |

| Heating Method |

Electric heating |

| Two Cold Plates |

Water cooling laminates temperature controlled by water temperature |

| Cooling Method |

Tap water cooling/chiller cooling |

| Hydraulic System |

CREE.6 hydraulic flow closed-loop control system is adopted, the oil pump drives high-performance electro-hydraulic and the piston of high-precision non-resistance oil cylinder executes the constant-rate control mode, and has the function of automatic pressure compensation. One-time pressurization automatically compensates for pressure, with strong load force and stable lifting. Automatic pressurization, maintenance and pressure relief. |

| Cylinder Stroke |

Max 150mm [customizable] |

| Cylinder Rate |

11mm/s |

| Pressure Gauge |

0~200kg/sq.cm |

| Mold Opening Method |

Fully automatic rise and fall (with manual and automatic dual functions) |

| Safety Devices |

Safety shield, safety gate. |

| Number of Safety Devices |

4 pieces |

| Matching Mold Frame [optional] |

Customized |

| Host Volume |

(W×D×H)1100×550×1500 mm |

(W×D×H)1100×650×1500 mm |

(W×D×H)1200×750×1650 mm |

| Voltage |

3∮,AC220V |

3∮,AC380V |

3∮,AC380V |

| Total Weight |

≈550kg |

≈700kg |

≈780kg |

►Specifications:

►Configuration List:

| Name |

Quantity |

| AC Motor |

1 set |

| Vulcanizer Motherboard |

1 set |

| Upper and Lower Die Sensor |

2sets |

| 30T Oil Cylinder |

1set |

| Hydraulic Station |

1set

|

| RVG-03 Guided Relief Valve |

1set |

| Control System |

1set |

| Touch Screen |

16 roots |

| Upper and Lower Die |

1set |

| Heating Pipe |

1set |

| Filter |

1set |

| Pressure Transmitters |

1set |

| Pressure Module |

1set |

| Exhaust Fan |

1set |

| Leakage Protector |

up and down |

| Fuse |

3sets |

| Cavity Protection Electric Box |

3sets |

| The Electromagnetic Valve |

2sets |

| Contactor |

some |

| Solid State |

1set |

| Electric Wire |

16 roots |

| Host |

1set |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!