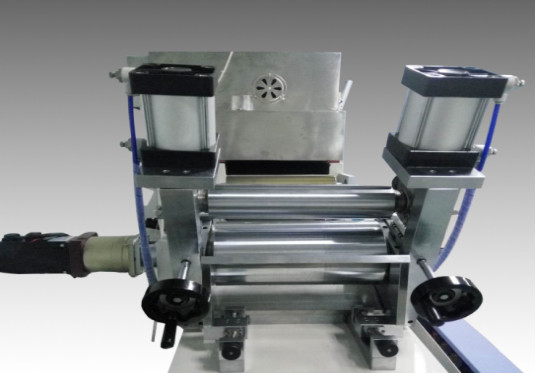

Solvent Based Experimental Coating Tape Adhesive Manufacture Machine

Product Description:

1. The frame is made of stainless steel plate welded and precision sprayed with surface treatment;

2. The installation method of retracting and unwinding coil material adopts air expansion shaft, which is marked with scale to facilitate loading alignment;

3. Automatic and manual tension control system is adopted to control the tension of winding and unwinding;

Characteristics of cloth applicator:

1. The maximum width within the coating width is 250mm (can be customized according to customer requirements);

2. The comma scraper can be lifted and lowered rapidly through the air cylinder, which is convenient for cleaning. A stainless steel waste plate is added to ensure the cleanness of the machine;

3. The gluing pressure is controlled by precisely adjusting the air pressure;

4. The coating gap is adjusted from both sides through a small hand wheel, and the coating gap is checked with a Japanese Sanfeng dial indicator, which is more convenient, fast and accurate;

5. The clearance adjustment range of comma scraper is 0-0.18mm (customized according to customer requirements);

6. There are three kinds of coating methods, i.e. comma head, concave head and cloth head, which can be coated at any time.

(Note: it is internally defined as comma roll coating head, which is equipped as standard. If other coating methods are required, please specify)

Oven features:

1. Five section hot air circulation dry stove, with a total length of 2.5m (0.5m * 5), and independent automatic temperature control in the range of normal temperature ~ 200 ℃;

2. Independent ventilation and dehumidification system;

3. The electric opening and closing system makes it more convenient to take and place the coated substrate;

4. Oven length and baking method can be customized according to customer requirements.

5. The whole machine adopts six servo motors for transmission, with simple structure and better synchronization, so as to reduce the failure rate of the machine;

6. The coating speed is adjustable, and the coating speed can be displayed at 0.3-6 M / min;

7. The whole machine is exquisite, takes up a small space and uses less proofing glue (about 50g can be proof

ed).

Reference Pictures:

A peel test is used for the testing of the bond of the adhesive between a flexible substrate and rigid substrate or two flexible substrates. When a flexible material is bonded to a rigid material either a 90 or 180 degree peel test will be used.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!